This Is What it Means to Be Customizable

In the first article of the Pass Muster Series, we mentioned Nippon Sharyo and the specifications they presented for the UP train in Toronto; but they’re not the only example of TMV Customization. In fact, every TMV customer has individual project requirements of some kind.

Normally, public projects such as passenger trains and streetcars have a list of specifications in a formal contract. For other projects, the expectations are much the same, but come to us more informally. For example, our team listens to our customers’ wishes and current frustrations and concerns, our engineers and managers look over vehicle schematics, and from there lists of features and solutions are generated.

These features and solutions are essentially practical specifications, and are at the heart of what TMV is all about. From retrofitting older locomotives to making sure a new connector is military grade, the range of customization seen across TMV’s project history is, (in informal terms), really cool.

What follows is a buffet of TMV customization examples. We’ve responded to individual customer requirements in so many different ways, it would have been a lengthy article to present them all. Here are quick summaries of some of the coolest. Enjoy!

El Paso Streetcars

Streetcars for El Paso – Entire rebuild done by Brookville Equipment, fitted with TECU propulsion control system. Here are a few examples of requirements met:

- Required upgraded electrical components to ensure 20 additional years of reliable operation.

- Intent to produce vehicles with high reliability and to minimize in-service delays.

- Contract outlined a required minimum of ten years previous experience. TMV and Brookville Equipment were chosen based on their experience with the New Orleans Streetcars.

- Technical Specifications set out as to be acceptable to the CRRMA and therefore comply with IEEE standards.

- Noise limitations were set to be acceptable in city streets at any time, but also, interestingly, to avoid making high-pitched sounds that could disturb canine guides.

- TMV had to ensure that all propulsion, braking and other TECU-controlled systems could accommodate track configurations, including speed limits and timeframes, stops and starts, incline grades and potentially rough crossings, which can jostle electrical equipment.

- TMV as subcontractor was required by contractor (Brookville Equipment) and CRRMA to possess all assets, skills and experience needed to perform all the elements of the scope of work outlined.

https://smartgrowthamerica.org/el-paso-is-rolling-again-with-its-1970s-streetcars/

http://www.sunmetro.net/streetcar

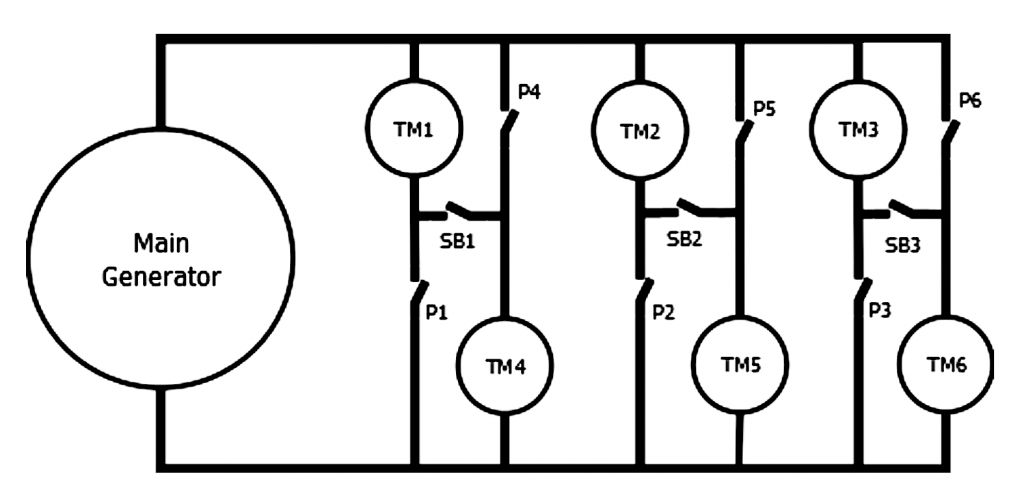

1200hp Switcher GenSet

Required:

SW1200 Gen-set: Repowered locomotive to comply with EPA title 40 part 92 requirements, and meet all applicable state regulations where the unit would operate (Delaware, New Jersey and Pennsylvania).

TMV asked to provide:

- Individual axle control

- Individual motor cut-out

- An idle stop scheme that conforms to AAR S-5502

- A minimum of 30% adhesion in all weather conditions

In this case, the customer reserved the right to verify compliance with the contractor’s quality assurance program, which was to be based on AAR/M-1003, Mil STD 9858A, ISO 9000, or ASQC Q90.

- Pike’s Peak Cog train, and Peru Rail’s train by PYSC (Productos y Servicios del Centro). Both operating at high altitudes, and in changing temperatures and humidity levels, they needed control systems that wouldn’t glitch or fail. Both these trains reach altitudes close to 14,000ft above sea level, and have three braking systems. https://www.perurail.com/destinations/cusco-machu-picchu/

https://en.wikipedia.org/wiki/PeruRail https://www.cograilway.com

- Road Switchers for passenger or freight service benefit from the TECU’s “transition smoothing”, which helps prevent excessive torque or jerk on the coupling.

- Wet weather is known to cause nuisance Ground Relay trips. To take care of this, TMV provides Automatic Ground Relay Reset.

- Norfolk Southern’s DC2AC project required an electrical cabinet, which TMV has experience making. However, they also required an entire Electrical Room. This was a first for TMV but enthusiastically accommodated. TMV worked with CAF Power & Automation for this project.

- TMV’s AESS (Auto Engine Start Stop) was put on SmartWay’s verified list of Idling Reduction Technologies. A customer asked TMV to add our AESS to the EPA electronic database, (known as Umler,) to ease locomotive rebuilder’s administration processes. The TMV AESS is designed and built according to AAR S-5502 standards.

Thank you for reading, for other articles in the series:

Introduction – TMV Claims to Pass Muster

Pass Muster – 1 – Capability Test Report for Nippon Sharyo

Pass Muster – 2 – The Railway Industry and ISO 9001

Pass Muster – 3 – Trade-shows and Memberships

Conclusion – Quality Policy and the Workplace